As global efforts to achieve net-zero emissions accelerate, forest resources have become increasingly precious—closely tied to international carbon credit systems.

This has placed constraints on the use of solid wood materials in the decoration, flooring, and furniture industries, raising the value of timber and driving demand for resource-efficient technologies.

INNOVATOR MACHINERY CO., LTD. (INNOVATOR) has embraced this shift by focusing on intelligent veneer processing solutions that align with environmental sustainability.

Founded in 2003, INNOVATOR developed veneer lamination technologies that enhance wood utilization by bonding ultra-thin veneer to engineered wood substrates.

Its systems can process veneer as thin as 0.2 mm—delivering cost savings while preserving the natural aesthetics of wood, meeting consumer demand for sustainable design.

Following the 2007 financial crisis, INNOVATOR entered into a technical partnership with Europe’s SAVI, a major veneer shear manufacturer, enabling it to offer full production lines.

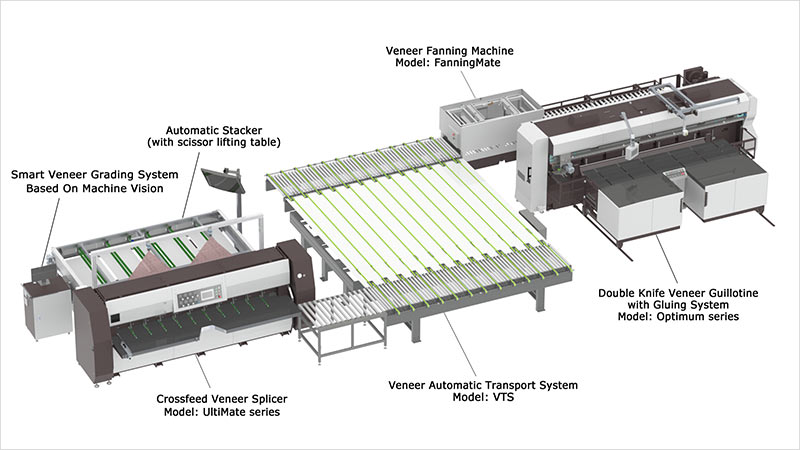

Today, the company supplies a complete range of machines including shearing machines, glue applicators, spreaders, stitchers, edge trimmers, and automatic stackers—providing a one-stop solution for veneer processing.

Post-crisis, the rise of Industry 4.0 catalyzed a new wave of smart manufacturing. INNOVATOR responded by launching Asia’s first fully automated veneer production line in 2015.

This reduced manual handling losses, improved yield, and eased labor shortages—positioning INNOVATOR among the top three veneer equipment manufacturers worldwide.

Even amid the US-China trade war and the reshuffling of global supply chains, INNOVATOR leveraged its early experience navigating the relocation of furniture industries.

Its leadership team visited over 30 countries and participated in international exhibitions to promote the brand, backed by a strong service strategy and feedback-driven R&D.

As of 2019, INNOVATOR has established a global network of distributors and sold over 1,000 machines in more than 50 countries.

The company continues to expand its product offerings and aims to become the global leader in veneer equipment manufacturing.

To further enhance automation, INNOVATOR collaborated with the Precision Machinery Research & Development Center (PMC) to develop Asia’s first smart veneer line (W-Team 6).

This line integrated double-knife shears, crosswise stitchers, and edge trimmers—reducing required labor from 10 to 3 operators.

The final output is suitable for furniture and interior materials, and INNOVATOR was the only vendor to successfully commercialize its line during the project phase.

Currently, the company is integrating remote monitoring capabilities by installing sensors to track utilization rates and improve management efficiency.

With PMC’s support, INNOVATOR is also introducing AI+AOI systems to inspect and grade veneer surfaces—eliminating reliance on manual visual checks.

This boosts both inspection speed and grading accuracy, addressing key pain points for traditional manufacturers.

INNOVATOR looks forward to showcasing its cutting-edge veneer solutions at the upcoming LIGNA trade fair and invites industry professionals to explore opportunities for collaboration in sustainable wood processing.