Based on the current international trend of net-zero carbon emissions, the energy and aerospace industries are bound to expand investment, driving the vigorous development of upstream and downstream supply chains. Honor Seiki, focusing on vertical lathes/turning centers and large gantry-type milling-turning centers, and adding value through intelligent software application solutions, is mainly applied in high-end industrial fields such as aerospace, renewable energy, rail transportation, and bearings. Marketing internationally under the "HONOR" brand, it directly competes with major European and Japanese manufacturers.

Among them, the renewable energy field directly related to Honor Seiki is the wind power industry. The main selling models are mostly large-scale, highly complex, and customized applications. It has also long focused on improving turning accuracy and OEE (Overall Equipment Effectiveness) automated production efficiency and other high-value technical thresholds, positioning itself in the high-end customer market, thus avoiding price competition with counterparts in mainland China and Taiwan or Japanese and Korean manufacturers to ensure its profitability and maintain its leading brand position in the field of high-precision and high-efficiency vertical lathes.

With the rise of the hydrogen energy industry in recent years, the demand for key components of generators and high-pressure hydrogen storage equipment has increased significantly. Honor Seiki has also received orders for processing machines from a leading European hydrogen equipment manufacturer, and with the required fixtures, completed an automated demonstration production line for hydrogen production machines, entering the European hydrogen energy market, and is expected to export entire production lines to India, the United States, and other places in the future.

Joseph Chen, General Manager of Honor Seiki, further pointed out that since Honor Seiki's performance mostly reflects customer investment in expanding production capacity and purchasing equipment, some customers are currently evaluating setting up factories in Thailand or Malaysia. Optimistic about the aerospace engine manufacturing market in Malaysia, they may initially use European five-axis models combined with Honor Seiki's vertical lathes and intelligent solutions to improve customer efficiency by more than 30%. After completing the learning curve, they will begin to consider fully introducing Taiwanese-made models.

For example, in the field of aerospace engine processing, Honor Seiki can solve many problems such as measurement and deformation prevention according to the different levels of automation of individual workpieces, realizing single-machine automation. The vertical lathe specially developed for the efficient processing of new-generation LEAP engine parts is equipped with a dual-pallet automatic exchange system, allowing parts to be processed inside the machine while another part can continue to perform processes such as calibration, unloading, and loading on the automatic exchange table outside the machine, which will greatly improve machine utilization and help customers reduce costs.

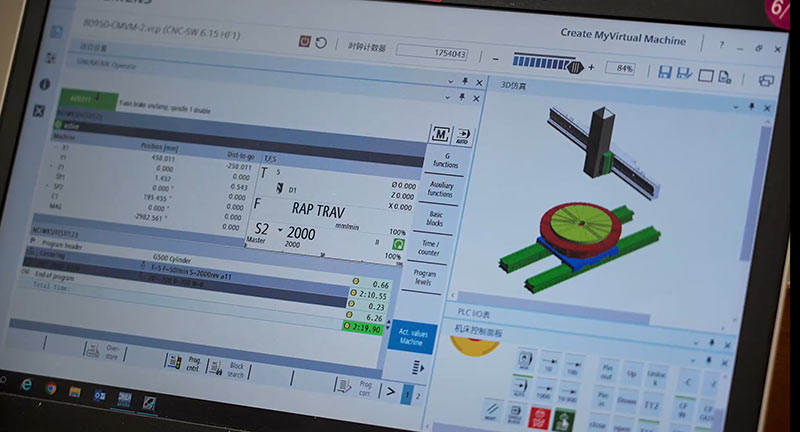

Honor Seiki is also cooperating with its related enterprise Tongtai Machine & Tool in the software of the TLM production line monitoring system, which belongs to a part of the visualization system, collecting data that has already occurred; and through long-term planning of digital twins, presenting future production capacity configuration and optimal production conditions, enabling advance planning of machine capacity and utilization rate. And using simulation to greatly reduce the machine's testing and preparation time by 20%, without having to wait until the machine is assembled before actual trial processing.

In the field of AIoT, Honor Seiki also took advantage of the trend to launch the "Machine Online Precision Autonomous Inspection System" this year. When a sensor detects a precision deviation, it immediately issues a warning and notifies the engineer to calibrate and confirm before processing to prevent large machines from being affected by earthquakes or collisions, which would affect precision, and finding out only after processing defective products would be too late. This helps customers solve the pain points of labor shortages, small-volume and high-variety orders, and large and complex workpiece processing, and can also easily grasp production efficiency and energy consumption status, which can reduce carbon emissions by about 23%.

Secondly, the introduction of AI cutting applications is different from other milling machine manufacturers that already have cutting sensing and judgment systems. Only large global lathes have not yet had successful cases. Honor Seiki has spent 10 years developing a real-time tool detection and compensation system. If it is found that there are signs of tool breakage, air cutting, or excessive wear during the cutting process, the machine will automatically issue a warning and stop within 1ms to avoid producing defective products; in the long term, it will also invest in developing tool life pre-diagnosis functions. Through the online machine learning system for continuous calculation, it will first be installed at a French aerospace customer's site for testing by the end of this year.

It is also currently cooperating with PMC on carbon inventory, introducing variable frequency applications to improve power consumption of peripheral equipment and systems; then redesigning its own machines, reviewing the carbon footprint of each workpiece, and is expected to pass ISO14955 certification next year, thereby improving energy consumption optimization to create value for customers. Honor Seiki aims to become the customer's preferred global high-efficiency smart vertical lathe strategic partner in the future, by helping customers carry out machine intelligent upgrades, improve production efficiency, quality, accuracy and reliability, reduce costs and carbon emissions, and significantly enhance market competitiveness.