To embrace the era of generative AI, the application of AIoT needs to be accelerated. NEXCOM Group's "NexAIoT," a subsidiary of the industrial computer giant, recently launched its latest factory management generative AI command center smart assistant. It specifically addresses issues faced by on-site manufacturing managers, including non-real-time on-site information, labor shortages, electricity consumption problems, product history tracking, product carbon footprint, quality reports, etc., providing optimal solutions while responding to global goals of Earth sustainability and net-zero carbon emissions.

Although through the previous wave of Industry 4.0 and digital transformation, most manufacturing industries have gradually transitioned from relying on manual paper records to using machine networking to successfully digitized data, and have now evolved to the stage of data AI-ization. However, in the actual process of introducing digitization, the challenges encountered by first-line managers are gradually emerging, and there is still a gap between the reality and the ideal of factory digitization.

Tim Juan, Vice President of NexAIoT, views the current development trend of AI and also recognizes the difficulty of AIoT implementation. The promotion of related solutions must be driven by SI (System Integration) departments, which is based on NexAIoT's own strengths. Coupled with its open characteristics, it allows customers to freely choose the most cost-effective solutions. Regardless of whether the equipment is new, old, or networkable, it can be quickly connected to solve customer pain points, make AI applications more popular, and enhance customer market competitiveness.

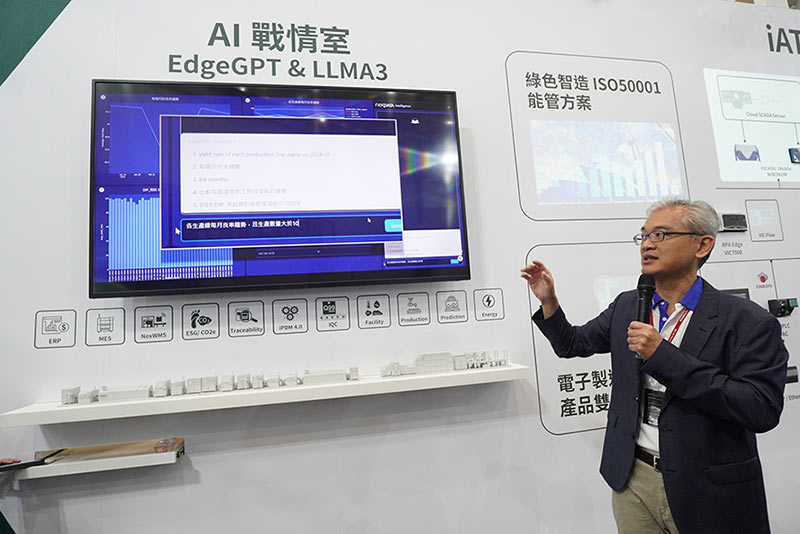

Since building a smart manufacturing data middle platform in 2020, NexAIoT, driven by generative AI technology, has developed an artificial intelligence assistant designed specifically for the manufacturing industry - the NexAIoT Enterprise Command Center Smart Assistant. It emphasizes the interconnection of equipment at all levels under the NexAIoT iAT2000 architecture, including the key smart IoT innovative device nDAS and the NexDATA data integration platform, realizing the digital analysis functions that the next generation of smart factories should have.

Among them, nDAS is positioned as an I/O port receiver and adds a visual screen, allowing users to more quickly visually read data directly from the terminal equipment, which is quite popular in emerging Asian markets such as Indonesia. Coinciding with the current ESG trend, the demand for recorded data during the production process has increased rapidly. Through nDAS, carbon emission factor data during the production process is collected and transmitted to NexDATA for data integration, and finally presented in NexAIoT's AI command center carbon footprint module, which also solves the past dilemma often encountered by customers when implementing machine networking and automation in Industry 4.0: the large amounts of data collected had nowhere to be used.

NexAIoT, through long-term front-line service to automation industry customers, has also found that although the AI command center systems that are gradually being widely introduced into manufacturing sites can be customized, the data generation is still limited to customized "static fixed parameters," such as production yield, man-hour efficiency, production time, and incoming material control. However, there are multiple variables in the manufacturing site. Once these traditional command centers show a factory accident, management often requires on-site engineers to spend a lot of time retrieving data and then organizing a response. The current method of using customized pre-set templates cannot effectively respond to the daily changing factors encountered in the manufacturing site.

In recent years, with the rise of generative AI, NexAIoT has begun to develop the manufacturing industry AI enterprise command center "NexAIoT Enterprise Command Center Smart Assistant." Through the self-developed NexDATA, the huge database accumulated over many years is connected to the large language model (LLM) system. NexDATA transforms the factory-side database into an intuitive query expert knowledge base, allowing the AI command center smart assistant to assist enterprise executives in data analysis. It also uses RAG (Retrieval Augmented Generation) technology, so that the AI command center smart assistant does not need to be bound to a specific LLM system, making it adaptable to the ever-changing and constantly updated LLMs. In addition, the problem of high fine-tuning costs often worried about by small and medium-sized enterprises (SMEs) can be dispelled by using RAG technology.

NexAIoT's AI command center smart assistant uses its own design team to create an intuitive user interface and also supports text, tables, and diverse chart presentation methods, allowing factory managers to make any data requests without restriction, so as to obtain the required information in real time and find pain points, intuitively generate real-time management dashboards and reports, greatly shortening manpower working hours and helping enterprises improve production efficiency and shorten exploration time.

Tim Juan pointed out that currently, NexAIoT's internal ERP, MES, and other IT business systems input data into the NexDATA data integration platform, which is responsible for executing the connection operations between various systems. This can prevent system data integration operations from being executed on various IT business systems, affecting normal operation or slowing down production efficiency, breaking through process pain points, overcoming cross-system data integration obstacles, and allowing the NexDATA data integration platform to provide a production history module on the command center to help trace and improve production processes, and use the carbon footprint module to track the improvement of carbon emissions to achieve ESG vision.

In addition, the NexAIoT Enterprise Command Center Smart Assistant is also one of the few innovative products that have entered the market application stage. For traditional factories, after digital transformation, they usually build command centers to monitor factory operations. However, when facing problems such as declining sales data and low product yields, they often rely on the Management Information Systems (MIS) department to spend 1-4 weeks to find the root cause of the problem. After introducing the NexAIoT Enterprise Command Center Smart Assistant, AI can also quickly find data from the database and provide solutions to the root of the problem.

Tim Juan emphasized that due to NexAIoT's SI background advantages, it advocates that data sorting is the most important first step and then gradually introduce AI. It also understands how to repeatedly and correctly use data at a faster speed. From production history to tracking carbon footprints, about 80% of the data can be reused. The three selling points of the NexAIoT Enterprise Command Center Smart Assistant include: 1. Pure on-premise to ensure privacy, 2. Based on a reliable database to avoid misleading responses, 3. The model can be updated regularly.

"Now companies have changed to first training their own database to establish small and medium-sized language model data, which is like training multiple Poké Balls, rather than just selling a single AI model," Tim pointed out. NexAIoT, starting from the role of data manager, in addition to empowering SME customers to continuously keep up with the times, can also use affordable costs to update small language algorithm models. For large enterprises, it can also provide differentiated advantages of on-premise and cloud-based solutions different from other startups, and avoid inadvertent leakage of confidential know-how.